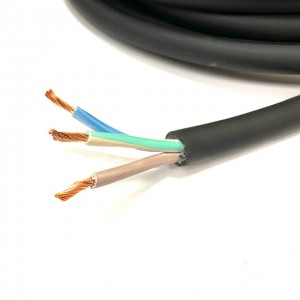

H07RN-F Rubber Sheathed Flexible Cable

Application

Rubber cable are designed to provide high flexibility and have the capacity to withstand weather, oil/grease, mechanical and thermal stresses. Applications include handling equipment, mobile power supplies, worksites, stage and audio visual equipment, port areas and dams. The cables are used in drainage and water treatment, cold environments and severe industrial environments. Also used as electrical connect line or wiring in power installation, household appliances, electrically operated tools, instruction lighting and machines inner rated voltage A.C 450/750V or below.

Constrution

Characteristics

| Rated voltage(U0/U) | 450/750V |

| Insulation material | Rubber compound |

| Sheath material | Rubber compound(CPE) |

| Permissible continuous working temperature |

Not exceed 60°C |

| Test voltage | 2500 volts |

| Flexing bending radius | 6 x Ø |

| Fixed bending radius | 4.0 x Ø |

| Flexing Temperature | 25ºC to +60ºC |

| Fixed Temperature | 40ºC to +60ºC |

| Short circuit temperature | +200ºC |

| Insulation resistance | 20 MΩ x km |

| Cross sectional area | 1.5mm2- 400mm2 |

| Cores | 1core; 2 core; 3core; 4core; 5core; 3+1core |

Parameters

|

1 Core H07rn-f Rubber Cable |

||||||||

|

Size |

Nominal Insulation Thickness |

Minimum Insulation Thickness |

Nominal Jacket Thickness |

Minimum Jacket Thickness |

Nominal Overall Diameter ±8% |

Approx. Cable Weight |

Nominal Current ar air temp. 30°C |

|

|

mm2 |

mm |

mm |

mm |

mm |

mm |

KG/KM |

Mobile |

Fixed |

|

1×1.5 |

0.8 |

0.7 |

1.4 |

1.1 |

5.8 |

52 |

16.5 |

23 |

|

1×2.5 |

0.9 |

0.7 |

1.4 |

1.1 |

6.3 |

66 |

22 |

32 |

|

1×4 |

1 |

0.7 |

1.5 |

1.2 |

7.2 |

89 |

30 |

43 |

|

1×6 |

1 |

0.7 |

1.6 |

1.3 |

7.9 |

113 |

38 |

56 |

|

1×10 |

1.2 |

1 |

1.8 |

1.4 |

9.5 |

170 |

53 |

77 |

|

1×16 |

1.2 |

1 |

1.9 |

1.5 |

10.6 |

229 |

71 |

102 |

|

1×25 |

1.4 |

1.2 |

2 |

1.6 |

12.4 |

327 |

94 |

136 |

|

1×35 |

1.4 |

1.2 |

2.2 |

1.8 |

13.8 |

422 |

117 |

168 |

|

1×50 |

1.6 |

1.3 |

2.4 |

1.9 |

16 |

583 |

148 |

203 |

|

1×70 |

1.6 |

1.3 |

2.6 |

2.1 |

17.8 |

763 |

185 |

254 |

|

1×95 |

1.8 |

1.5 |

2.8 |

2.3 |

20.2 |

1003 |

222 |

299 |

|

1×120 |

1.8 |

1.5 |

3 |

2.5 |

22.1 |

1222 |

260 |

363 |

|

1×150 |

2 |

1.7 |

3.2 |

2.6 |

24.3 |

1497 |

300 |

416 |

|

1×185 |

2.2 |

1.9 |

3.4 |

2.8 |

26.6 |

1822 |

341 |

475 |

|

1×240 |

2.4 |

2.1 |

3.5 |

2.9 |

29.4 |

2298 |

407 |

559 |

|

1×300 |

2.6 |

2.2 |

3.6 |

3 |

32.2 |

2816 |

468 |

637 |

|

1×400 |

2.8 |

2.4 |

3.8 |

3.1 |

35.9 |

3615 |

468 |

637 |

|

2 Core H07rn-f Rubber Cable |

||||||||

|

Size |

Nominal Insulation Thickness |

Minimum Insulation Thickness |

Nominal Jacket Thickness |

Minimum Jacket Thickness |

Nominal Overall Diameter ±8% |

Approx. Cable Weight |

Nominal Current ar air temp. 30°C |

|

|

mm2 |

mm |

mm |

mm |

mm |

mm |

KG/KM |

Mobile |

Fixed |

|

2×1.0 |

0.8 |

0.6 |

1.3 |

1 |

8 |

96 |

10 |

18 |

|

2×1.5 |

0.8 |

0.6 |

1.5 |

1.2 |

8.9 |

122 |

16 |

23 |

|

2×2.5 |

0.9 |

0.7 |

1.7 |

1.3 |

10.5 |

172 |

25 |

32 |

|

2×4 |

1.0 |

0.8 |

1.8 |

1.4 |

12 |

233 |

34 |

43 |

|

2×6 |

1.0 |

0.8 |

2.0 |

1.6 |

13.4 |

299 |

43 |

56 |

|

2×10 |

1.2 |

1.0 |

3.1 |

2.5 |

18.2 |

538 |

60 |

77 |

|

2×16 |

1.2 |

1.0 |

3.3 |

2.7 |

20.4 |

709 |

79 |

102 |

|

2×25 |

1.4 |

1.2 |

3.6 |

3.0 |

24.3 |

1021 |

105 |

136 |

|

2×35 |

1.4 |

1.2 |

3.8 |

3.1 |

26.7 |

1275 |

130 |

168 |

|

2×50 |

1.6 |

1.3 |

4.2 |

3.5 |

31.1 |

1758 |

160 |

203 |

|

2×70 |

1.6 |

1.3 |

4.6 |

3.8 |

34.7 |

2269 |

196 |

254 |

|

2×95 |

1.8 |

1.5 |

5.0 |

4.2 |

39.5 |

2978 |

238 |

299 |

|

3 Core H07rn-f Rubber Cable |

||||||||

|

Size |

Nominal Insulation Thickness |

Minimum Insulation Thickness |

Nominal Jacket Thickness |

Minimum Jacket Thickness |

Nominal Overall Diameter ±8% |

Approx. Cable Weight |

Nominal Current ar air temp. 30°C |

|

|

mm2 |

mm |

mm |

mm |

mm |

mm |

KG/KM |

Mobile |

Fixed |

|

3×1.0 |

0.8 |

0.6 |

1.4 |

1.1 |

8.6 |

115 |

10 |

18 |

|

3×1.5 |

0.8 |

0.6 |

1.6 |

1.3 |

9.6 |

146 |

16 |

23 |

|

3×2.5 |

0.9 |

0.7 |

1.8 |

1.4 |

11.2 |

206 |

25 |

32 |

|

3×4 |

1.0 |

0.8 |

1.9 |

1.5 |

12.8 |

282 |

35 |

43 |

|

3×6 |

1.0 |

0.8 |

2.1 |

1.7 |

14.3 |

363 |

44 |

56 |

|

3×10 |

1.2 |

1.0 |

3.3 |

2.7 |

19.5 |

654 |

60 |

77 |

|

3×16 |

1.2 |

1.0 |

3.5 |

2.9 |

21.9 |

870 |

82 |

102 |

|

3×25 |

1.4 |

1.2 |

3.8 |

3.1 |

26.0 |

1257 |

109 |

136 |

|

3×35 |

1.4 |

1.2 |

4.1 |

3.4 |

28.8 |

1593 |

135 |

168 |

|

3×50 |

1.6 |

1.3 |

4.5 |

3.7 |

33.4 |

2198 |

169 |

203 |

|

3×70 |

1.6 |

1.3 |

4.8 |

4.0 |

37.1 |

2832 |

211 |

254 |

|

3×95 |

1.8 |

1.5 |

5.3 |

4.4 |

42.4 |

3747 |

250 |

299 |

|

3×120 |

1.8 |

1.5 |

5.6 |

4.7 |

46.2 |

4528 |

290 |

263 |

|

3×150 |

2.0 |

1.7 |

6.0 |

5.0 |

50.9 |

5549 |

332 |

416 |

|

4 Core H07rn-f Rubber Cable |

||||||||

|

Size |

Nominal Insulation Thickness |

Minimum Insulation Thickness |

Nominal Jacket Thickness |

Minimum Jacket Thickness |

Nominal Overall Diameter ±8% |

Approx. Cable Weight |

Nominal Current ar air temp. 30°C |

|

|

mm2 |

mm |

mm |

mm |

mm |

mm |

KG/KM |

Mobile |

Fixed |

|

4×1.0 |

0.8 |

0.6 |

1.5 |

1.2 |

9.5 |

141 |

10 |

16 |

|

4×1.5 |

0.8 |

0.6 |

1.7 |

1.3 |

10.5 |

179 |

16 |

21 |

|

4×2.5 |

0.9 |

0.7 |

1.9 |

1.5 |

12.3 |

253 |

20 |

29 |

|

4×4 |

1.0 |

0.8 |

2 |

1.6 |

14.1 |

348 |

30 |

38 |

|

4×6 |

1.0 |

0.8 |

2.3 |

1.9 |

15.9 |

457 |

37 |

50 |

|

4×10 |

1.2 |

1.0 |

3.4 |

2.8 |

21.2 |

797 |

52 |

68 |

|

4×16 |

1.2 |

1.0 |

3.6 |

3.0 |

23.8 |

1068 |

69 |

92 |

|

4×25 |

1.4 |

1.2 |

4.1 |

3.4 |

28.8 |

1580 |

92 |

122 |

|

4×35 |

1.4 |

1.2 |

4.4 |

3.6 |

31.8 |

2004 |

114 |

150 |

|

4×50 |

1.6 |

1.3 |

4.8 |

4.0 |

36.9 |

2766 |

143 |

282 |

|

4×70 |

1.6 |

1.3 |

5.2 |

4.3 |

41.1 |

3592 |

178 |

232 |

|

4×95 |

1.8 |

1.5 |

5.9 |

4.9 |

47.3 |

4799 |

210 |

281 |

|

4×120 |

1.8 |

1.5 |

6.0 |

5.0 |

51.2 |

5739 |

246 |

325 |

|

4×150 |

2.0 |

1.7 |

6.5 |

5.4 |

56.5 |

7060 |

280 |

373 |

|

4×185 |

2.2 |

1.9 |

7 |

5.9 |

62.1 |

8613 |

330 |

424 |

|

4×240 |

2.4 | 2.1 | 7.7 | 6.4 | 69.8 | 11025 | 408 | 480 |

|

5 Core H07rn-f Rubber Cable |

||||||||

|

Size |

Nominal Insulation Thickness |

Minimum Insulation Thickness |

Nominal Jacket Thickness |

Minimum Jacket Thickness |

Nominal Overall Diameter ±8% |

Approx. Cable Weight |

Nominal Current ar air temp. 30°C |

|

|

mm2 |

mm |

mm |

mm |

mm |

mm |

KG/KM |

Mobile |

Fixed |

|

5×1.0 |

0.8 |

0.6 |

1.6 |

1.3 |

10.5 |

173 |

10 |

16 |

|

5×1.5 |

0.8 |

0.6 |

1.8 |

1.4 |

11.6 |

218 |

16 |

21 |

|

5×2.5 |

0.9 |

0.7 |

2.0 |

1.6 |

13.5 |

308 |

20 |

29 |

|

5×4 |

1.0 |

0.8 |

2.2 |

1.8 |

15.7 |

432 |

30 |

38 |

|

5×6 |

1.0 |

0.8 |

2.5 |

2.0 |

17.6 |

566 |

38 |

50 |

|

5×10 |

1.2 |

1.0 |

3.6 |

3.0 |

23.3 |

970 |

54 |

68 |

|

5×16 |

1.2 |

1.0 |

3.9 |

3.2 |

26.4 |

1316 |

71 |

92 |

|

5×25 |

1.4 |

1.2 |

4.4 |

3.6 |

31.8 |

1943 |

94 |

122 |

|

5×35 |

1.4 |

1.2 |

4.6 |

3.8 |

34.9 |

2444 |

114 |

150 |

|

5×50 |

1.6 |

1.3 |

5.2 |

4.3 |

40.9 |

3420 |

143 |

182 |

|

5×70 |

1.6 |

1.3 |

5.7 |

4.7 |

45.7 |

4462 |

178 |

232 |

|

5×95 |

1.8 |

1.5 |

6.3 |

5.3 |

52.3 |

5914 |

210 |

281 |

|

5×120 |

1.8 |

1.5 |

6.3 |

5.3 |

56.4 |

7050 |

246 |

325 |

|

5×150 |

2.0 |

1.7 |

6.8 |

5.7 |

62.2 |

8668 |

280 |

373 |

FAQ

Q: Can we have our logo or company name to be printed on your products or the package?

A: The OEM & ODM order is warmly welcome and we have fully successful experience in OEM projects. What's more, our R&D team will give you the professional suggestions.

Q: How does your company do regarding Quality Control?

A: 1)All raw material we selected the high quality one.

2)Professional & Skilful workers care every details in handling the producing.

3)Quality Control Department specially responsible for quality checking in each process.

Q: How can I get a sample to test your quality?

A: We can provide free samples for your test and checking, just need to bear the freight charge. mass production;

Our factory will always have a final Inspection before shipment.