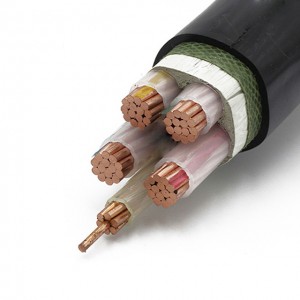

0.6/1kv CU/XLPE/PVC Unarmoured Power Cable

Application

The cables are used for electricity supply in low voltage installation system, They are suitable for installation in indoors and outdoors, in cable ducts, under ground, in power and switching stations, local energy distributions, industrial plants, where there is no risk of mechanical damage.

Constrution

Characteristics

Rated voltage: 0.6/1kV

1.during normal operation of cable, the maximum conductor temperature shall be 70℃ for PVC insulation and 90℃ for XLPE insulation.

2.Maximum temperature of conductor during short circuit (maximum duration not exceeding 5 seconds) : PVC insulation -- 160℃ for conductor cross section ≤300mm2, 140℃ for conductor cross section > 300mm2; Crosslinked PVC insulation at 250℃.

3.When laying cables, the ambient temperature shall not be less than 0℃, and the minimum allowable bending radius is as follows:

Single core cable: unarmored 20D, armored 15D

Multi-core cable: 15D for unarmored, 12D for armored

Where: D- actual outer diameter of cable.

4.Cable breaking force:

Aluminum core cable: 40×S (N)

Copper core cable: 70×S (N)

Note: S is the total cross-sectional area of the conductor

Standards

IEC 60502-1, GB/T 12706.1

Parameters

|

Single Core Power Cable |

||||||||

|

Nom. Cross-section of conductor |

Insulation Thickness |

Sheath Thickness |

Approx. O.D. |

Approx Weight |

Max. D.C. Resistance of Conductor (20°C) |

Test Voltage A.C |

Current Rating |

|

|

mm2 |

mm |

mm |

mm |

kg/km |

Ω/km |

kV/5min |

In air(A) |

In soil(A) |

|

1×1.5 |

0.7 |

1.4 |

6 |

53 |

12.1 |

3.5 |

22 |

33 |

|

1×2.5 |

0.7 |

1.4 |

6 |

68 |

7.41 |

3.5 |

31 |

43 |

|

1×4 |

0.7 |

1.4 |

7 |

87 |

4.61 |

3.5 |

41 |

56 |

|

1×6 |

0.7 |

1.4 |

7 |

110 |

3.08 |

3.5 |

52 |

70 |

|

1×10 |

0.7 |

1.4 |

8 |

155 |

1.83 |

3.5 |

71 |

94 |

|

1×16 |

0.7 |

1.4 |

9 |

220 |

1.15 |

3.5 |

92 |

120 |

|

1×25 |

0.9 |

1.4 |

10 |

345 |

0.727 |

3.5 |

120 |

155 |

|

1×35 |

0.9 |

1.4 |

12 |

424 |

0.524 |

3.5 |

150 |

185 |

|

1×50 |

1 |

1.4 |

13 |

555 |

0.387 |

3.5 |

180 |

220 |

|

1×70 |

1.1 |

1.4 |

14 |

770 |

0.268 |

3.5 |

230 |

270 |

|

1×95 |

1.1 |

1.5 |

16 |

1040 |

0.193 |

3.5 |

285 |

320 |

|

1×120 |

1.2 |

1.5 |

18 |

1290 |

0.153 |

3.5 |

335 |

365 |

|

1×150 |

1.4 |

1.6 |

20 |

1590 |

0.124 |

3.5 |

385 |

410 |

|

1×185 |

1.6 |

1.6 |

22 |

1944 |

0.0991 |

3.5 |

450 |

465 |

|

1×240 |

1.7 |

1.7 |

25 |

2510 |

0.0754 |

3.5 |

535 |

540 |

|

1×300 |

1.8 |

1.8 |

27 |

3042 |

0.0601 |

3.5 |

620 |

610 |

|

1×400 |

2 |

1.9 |

31 |

3869 |

0.047 |

3.5 |

720 |

695 |

|

1×500 |

2.2 |

2.1 |

35 |

4910 |

0.0366 |

3.5 |

835 |

780 |

|

1×630 |

2.4 |

2.2 |

40 |

6220 |

0.0283 |

3.5 |

960 |

880 |

|

1×800 |

2.6 |

2.4 |

45 |

7870 |

0.0221 |

3.5 |

1110 |

970 |

|

1×1000 |

2.8 |

2.6 |

51 |

9804 |

0.0176 |

3.5 |

1230 |

1060 |

|

2 Core Power Cable |

||||||||

|

Nom. Cross-section of conductor |

Insulation Thickness |

Sheath Thickness |

Approx. O.D. |

Approx Weight |

Max. D.C. Resistance of Conductor (20°C) |

Test Voltage A.C |

Current Rating |

|

|

mm2 |

mm |

mm |

mm |

kg/km |

Ω/km |

kV/5min |

In air(A) |

In soil(A) |

|

2×2.5 |

0.7 |

1.8 |

11.8 |

151 |

7.41 |

3.5 |

26 |

35 |

|

2×4 |

0.7 |

1.8 |

12.7 |

198 |

4.61 |

3.5 |

34 |

45 |

|

2×6 |

0.7 |

1.8 |

13.7 |

250 |

3.08 |

3.5 |

43 |

57 |

|

2×10 |

0.7 |

1.8 |

15 |

374 |

1.83 |

3.5 |

60 |

77 |

|

2×16 |

0.7 |

1.8 |

17 |

518 |

1.15 |

3.5 |

83 |

105 |

|

2×25 |

0.9 |

1.8 |

20 |

772 |

0.727 |

3.5 |

105 |

125 |

|

2×35 |

0.9 |

1.8 |

22 |

1006 |

0.524 |

3.5 |

125 |

155 |

|

2×50 |

1 |

1.8 |

20 |

1365 |

0.387 |

3.5 |

160 |

185 |

|

2×70 |

1.1 |

1.8 |

21 |

1872 |

0.268 |

3.5 |

200 |

225 |

|

2×95 |

1.1 |

1.8 |

24 |

2475 |

0.193 |

3.5 |

245 |

270 |

|

2×120 |

1.2 |

1.8 |

27 |

3089 |

0.153 |

3.5 |

285 |

310 |

|

2×150 |

1.4 |

1.9 |

30 |

3834 |

0.124 |

3.5 |

325 |

345 |

|

3 Core Power Cable |

||||||||

|

Nom. Cross-section of conductor |

Insulation Thickness |

Sheath Thickness |

Approx. O.D. |

Approx Weight |

Max. D.C. Resistance of Conductor (20°C) |

Test Voltage A.C |

Current Rating |

|

|

mm2 |

mm |

mm |

mm |

kg/km |

Ω/km |

kV/5min |

In air(A) |

In soil(A) |

|

3×1.5 |

0.7 |

1.5 |

10 |

145 |

12.1 |

3.5 |

20 |

27 |

|

3×2.5 |

0.7 |

1.5 |

11 |

185 |

7.41 |

3.5 |

26 |

35 |

|

3×4 |

0.7 |

1.5 |

12 |

250 |

4.61 |

3.5 |

34 |

45 |

|

3×6 |

0.7 |

1.5 |

13 |

320 |

3.08 |

3.5 |

43 |

57 |

|

3×10 |

0.7 |

1.8 |

16 |

450 |

1.83 |

3.5 |

60 |

77 |

|

3×16 |

0.7 |

1.8 |

18 |

640 |

1.15 |

3.5 |

83 |

105 |

|

3×25 |

0.9 |

1.8 |

21 |

940 |

0.727 |

3.5 |

105 |

125 |

|

3×35 |

0.9 |

1.8 |

23 |

1260 |

0.524 |

3.5 |

125 |

155 |

|

3×50 |

1 |

1.8 |

23 |

1670 |

0.387 |

3.5 |

160 |

185 |

|

3×70 |

1.1 |

1.8 |

26 |

2280 |

0.268 |

3.5 |

200 |

225 |

|

3×95 |

1.1 |

1.9 |

30 |

3020 |

0.193 |

3.5 |

245 |

270 |

|

3×120 |

1.2 |

2 |

32 |

3790 |

0.153 |

3.5 |

285 |

310 |

|

3×150 |

1.4 |

2.2 |

37 |

4750 |

0.124 |

3.5 |

325 |

345 |

|

3×185 |

1.6 |

2.3 |

41 |

5654 |

0.0991 |

3.5 |

375 |

390 |

|

3×240 |

1.7 |

2.4 |

46 |

7243 |

0.0754 |

3.5 |

440 |

450 |

|

3×300 |

1.8 |

2.6 |

51 |

9465 |

0.0601 |

3.5 |

505 |

515 |

|

3×400 |

2 |

3 |

64 |

12066 |

0.047 |

3.5 |

570 |

575 |

|

4 Core Power Cable |

||||||||

|

Nom. Cross-section of conductor |

Insulation Thickness |

Sheath Thickness |

Approx. O.D. |

Approx Weight |

Max. D.C. Resistance of Conductor (20°C) |

Test Voltage A.C |

Current Rating |

|

|

mm2 |

mm |

mm |

mm |

kg/km |

Ω/km |

kV/5min |

In air(A) |

In soil(A) |

|

4×4 |

0.7 |

1.8 |

13 |

253 |

4.61 |

3.5 |

34 |

45 |

|

4×6 |

0.7 |

1.8 |

14 |

337 |

3.08 |

3.5 |

43 |

57 |

|

4×10 |

0.7 |

1.8 |

17 |

501 |

1.83 |

3.5 |

60 |

77 |

|

4×16 |

0.7 |

1.8 |

20 |

778 |

1.15 |

3.5 |

83 |

105 |

|

4×25 |

0.9 |

1.8 |

23 |

1160 |

0.727 |

3.5 |

105 |

125 |

|

4×35 |

0.9 |

1.8 |

25 |

1554 |

0.524 |

3.5 |

125 |

155 |

|

4×50 |

1 |

1.8 |

23 |

2148 |

0.387 |

3.5 |

160 |

185 |

|

4×70 |

1.1 |

1.8 |

27 |

2928 |

0.268 |

3.5 |

200 |

225 |

|

4×95 |

1.1 |

1.9 |

31 |

3854 |

0.193 |

3.5 |

245 |

270 |

|

4×120 |

1.2 |

2 |

33 |

4925 |

0.153 |

3.5 |

285 |

310 |

|

4×150 |

1.4 |

2.2 |

38 |

6238 |

0.124 |

3.5 |

325 |

345 |

|

4×185 |

1.6 |

2.3 |

42 |

7562 |

0.0991 |

3.5 |

375 |

390 |

|

4×240 |

1.7 |

2.5 |

47 |

9836 |

0.0754 |

3.5 |

440 |

450 |

|

4×300 |

1.8 |

2.6 |

52 |

12550 |

0.0601 |

3.5 |

505 |

515 |

|

4×400 |

2 |

3.1 |

66 |

15929 |

0.047 |

3.5 |

570 |

575 |

|

5 Core Power Cable |

||||||||

|

Nom. Cross-section of conductor |

Insulation Thickness |

Sheath Thickness |

Approx. O.D. |

Approx Weight |

Max. D.C. Resistance of Conductor (20°C) |

Test Voltage A.C |

Current Rating |

|

|

mm2 |

mm |

mm |

mm |

kg/km |

Ω/km |

kV/5min |

In air(A) |

In soil(A) |

|

5×4 |

0.7 |

1.8 |

14.5 |

349 |

4.61 |

3.5 |

34 |

45 |

|

5×6 |

0.7 |

1.8 |

15.8 |

460 |

3.08 |

3.5 |

43 |

57 |

|

5×10 |

0.7 |

1.8 |

19 |

699 |

1.83 |

3.5 |

60 |

77 |

|

5×16 |

0.7 |

1.8 |

22 |

1013 |

1.15 |

3.5 |

83 |

105 |

|

5×25 |

0.9 |

1.8 |

25 |

1566 |

0.727 |

3.5 |

105 |

125 |

|

5×35 |

0.9 |

1.9 |

28 |

2083 |

0.524 |

3.5 |

125 |

155 |

|

5×50 |

1 |

2 |

31 |

2921 |

0.387 |

3.5 |

160 |

185 |

|

5×70 |

1.1 |

2.1 |

36 |

3974 |

0.268 |

3.5 |

200 |

225 |

|

5×95 |

1.1 |

2.2 |

39 |

5297 |

0.193 |

3.5 |

245 |

270 |

|

5×120 |

1.2 |

2.4 |

44 |

6638 |

0.153 |

3.5 |

285 |

310 |

|

5×150 |

1.4 |

2.5 |

49 |

8290 |

0.124 |

3.5 |

325 |

345 |

|

5×185 |

1.6 |

2.7 |

55 |

10215 |

0.0991 |

3.5 |

375 |

390 |

|

5×240 |

1.7 |

3 |

64 |

13130 |

0.0754 |

3.5 |

440 |

450 |

|

5×300 |

1.8 |

3.2 |

70 |

16670 |

0.0601 |

3.5 |

505 |

515 |

|

3+1 Core Power Cable |

||||||||

|

Nom. Cross-section of conductor |

Insulation Thickness |

Sheath Thickness |

Approx. O.D. |

Approx Weight |

Max. D.C. Resistance of Conductor (20°C) |

Test Voltage A.C |

Current Rating |

|

|

mm2 |

mm |

mm |

mm |

kg/km |

Ω/km |

kV/5min |

In air(A) |

In soil(A) |

|

3×4+1×2.5 |

0.7 |

1.8 |

13 |

236 |

4.61 |

3.5 |

34 |

45 |

|

3×6+1×4 |

0.7 |

1.8 |

14 |

316 |

3.08 |

3.5 |

43 |

57 |

|

3×10+1×6 |

0.7 |

1.8 |

17 |

461 |

1.83 |

3.5 |

60 |

77 |

|

3×16+1×10 |

0.7 |

1.8 |

19 |

679 |

1.15 |

3.5 |

83 |

105 |

|

3×25+1×16 |

0.9 |

1.8 |

22 |

1065 |

0.727 |

3.5 |

105 |

125 |

|

3×35+1×16 |

0.9 |

1.8 |

24 |

1360 |

0.524 |

3.5 |

125 |

155 |

|

3×50+1×25 |

1 |

1.8 |

25 |

1901 |

0.387 |

3.5 |

160 |

185 |

|

3×70+1×35 |

1.1 |

1.9 |

28 |

2585 |

0.268 |

3.5 |

200 |

225 |

|

3×95+1×50 |

1.1 |

2 |

32 |

3518 |

0.193 |

3.5 |

245 |

270 |

|

3×120+1×70 |

1.2 |

2.1 |

35 |

4443 |

0.153 |

3.5 |

285 |

310 |

|

3×150+1×70 |

1.4 |

2.2 |

40 |

5326 |

0.124 |

3.5 |

325 |

345 |

|

3×185+1×95 |

1.6 |

2.4 |

43 |

8501 |

0.0991 |

3.5 |

375 |

390 |

|

3×240+1×120 |

1.7 |

2.5 |

48 |

11155 |

0.0754 |

3.5 |

440 |

450 |

|

3×300+1×150 |

1.8 |

2.7 |

54 |

14470 |

0.0601 |

3.5 |

505 |

515 |

|

3×400+1×240 |

2 |

3.1 |

66 |

309 |

0.047 |

3.5 |

570 |

575 |

|

3+2 Core Power Cable |

||||||||

|

Nom. Cross-section of conductor |

Insulation Thickness |

Sheath Thickness |

Approx. O.D. |

Approx Weight |

Max. D.C. Resistance of Conductor (20°C) |

Test Voltage A.C |

Current Rating |

|

|

mm2 |

mm |

mm |

mm |

kg/km |

Ω/km |

kV/5min |

In air(A) |

In soil(A) |

|

3×4+2×2.5 |

0.7 |

1.8 |

13.9 |

413 |

4.61 |

3.5 |

34 |

45 |

|

3×6+2×4 |

0.7 |

1.8 |

15.3 |

6682 |

3.08 |

3.5 |

43 |

57 |

|

3×10+2×6 |

0.7 |

1.8 |

18 |

603 |

1.83 |

3.5 |

60 |

77 |

|

3×16+2×10 |

0.7 |

1.8 |

21 |

888 |

1.15 |

3.5 |

83 |

105 |

|

3×25+2×16 |

0.9 |

1.8 |

24 |

1342 |

0.727 |

3.5 |

105 |

125 |

|

3×35+2×16 |

0.9 |

1.8 |

26 |

1647 |

0.524 |

3.5 |

125 |

155 |

|

3×50+2×35 |

1 |

1.9 |

29 |

2386 |

0.387 |

3.5 |

160 |

185 |

|

3×70+2×35 |

1.1 |

2 |

32 |

3201 |

0.268 |

3.5 |

200 |

225 |

|

3×95+2×50 |

1.1 |

2.1 |

36 |

4269 |

0.193 |

3.5 |

245 |

270 |

|

3×120+2×70 |

1.2 |

2.3 |

41 |

5437 |

0.153 |

3.5 |

285 |

310 |

|

3×150+2×70 |

1.4 |

2.4 |

44 |

6519 |

0.124 |

3.5 |

325 |

345 |

|

3×185+2×95 |

1.6 |

2.5 |

49 |

8101 |

0.0991 |

3.5 |

375 |

390 |

|

3×240+2×120 |

1.7 |

2.7 |

54 |

10340 |

0.0754 |

3.5 |

440 |

450 |

|

3×300+2×150 |

1.8 |

2.8 |

56 |

12810 |

0.0601 |

3.5 |

505 |

515 |

|

4+1 Core Power Cable |

||||||||

|

Nom. Cross-section of conductor |

Insulation Thickness |

Sheath Thickness |

Approx. O.D. |

Approx Weight |

Max. D.C. Resistance of Conductor (20°C) |

Test Voltage A.C |

Current Rating |

|

|

mm2 |

mm |

mm |

mm |

kg/km |

Ω/km |

kV/5min |

In air(A) |

In soil(A) |

|

4×4+1×2.5 |

0.7 |

1.8 |

14.5 |

331 |

4.61 |

3.5 |

34 |

45 |

|

4×6+1×4 |

0.7 |

1.8 |

15.9 |

435 |

3.08 |

3.5 |

43 |

57 |

|

4×10+1×6 |

0.7 |

1.8 |

18 |

649 |

1.83 |

3.5 |

60 |

77 |

|

4×16+1×10 |

0.7 |

1.8 |

21 |

965 |

1.15 |

3.5 |

83 |

105 |

|

4×25+1×16 |

0.9 |

1.8 |

25 |

1456 |

0.727 |

3.5 |

105 |

125 |

|

4×35+1×16 |

0.9 |

1.8 |

27 |

1863 |

0.524 |

3.5 |

125 |

155 |

|

4×50+1×25 |

1 |

1.9 |

29 |

2633 |

0.387 |

3.5 |

160 |

185 |

|

4×70+1×35 |

1.1 |

2 |

32 |

3565 |

0.268 |

3.5 |

200 |

225 |

|

4×95+1×50 |

1.1 |

2.1 |

36 |

4735 |

0.193 |

3.5 |

245 |

270 |

|

4×120+1×70 |

1.2 |

2.3 |

41 |

5977 |

0.153 |

3.5 |

285 |

310 |

|

4×150+1×70 |

1.4 |

2.4 |

44 |

7276 |

0.124 |

3.5 |

325 |

345 |

|

4×185+1×95 |

1.6 |

2.5 |

49 |

9055 |

0.0991 |

3.5 |

375 |

390 |

|

4×240+1×120 |

1.7 |

2.7 |

54 |

11567 |

0.0754 |

3.5 |

440 |

450 |

|

4×300+1×150 |

1.8 |

3.1 |

66 |

14321 |

0.0601 |

3.5 |

505 |

515 |

FAQ

Q: Can we have our logo or company name to be printed on your products or the package?

A: The OEM & ODM order is warmly welcome and we have fully successful experience in OEM projects. What's more, our R&D team will give you the professional suggestions.

Q: How does your company do regarding Quality Control?

A: 1)All raw material we selected the high quality one.

2)Professional & Skilful workers care every details in handling the producing.

3)Quality Control Department specially responsible for quality checking in each process.

Q: How can I get a sample to test your quality?

A: We can provide free samples for your test and checking, just need to bear the freight charge.